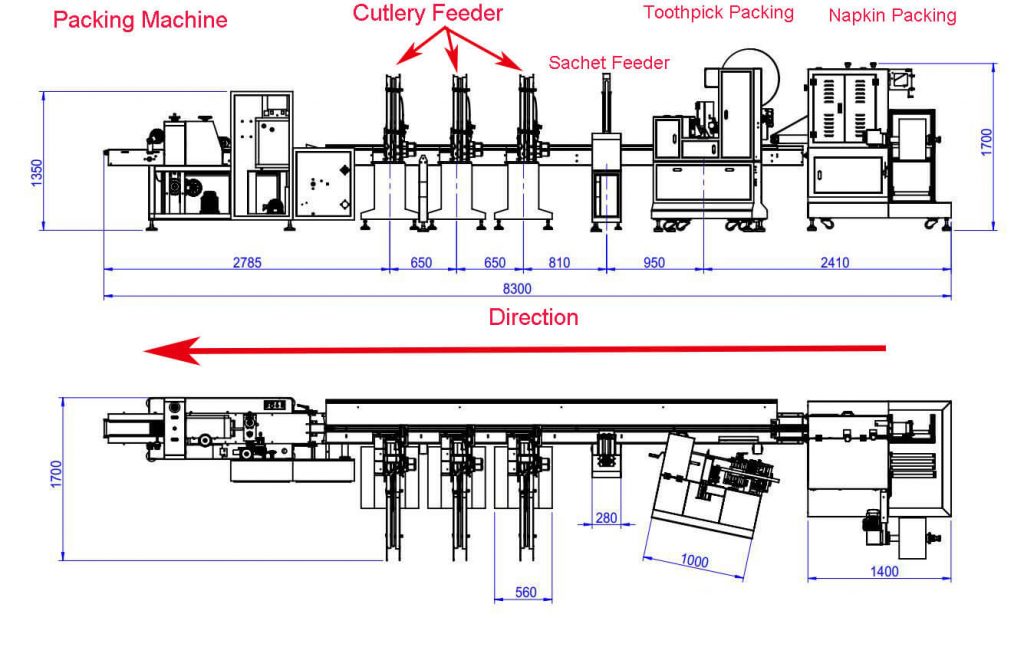

This machine is designed for napkin packaging and adopts vertical folding. It is an institution, fast speed, smooth operation and can automatically accomplish: paper napkin folding→ toothpick wrapping→automatic sugar/salt/pepper sachet feeder→automatic spoon feeder→ automatic fork feeder→ automatic knife feeder →pillow bag forming→products output.

Optional:

Air inflation, Pour slot, Printing code, Inkjet Printing, Exhaust.

| Model | JBK-250 |

|---|---|

| Napkin Roll Width | 80-330mm |

| Packing Material | OPP Film, Aluminum Laminated Film, Pure Aluminum Film, and other composite films |

| Packing Size | L:85-300mm W:30-100mm H:1-50mm |

| Packing Speed | 60-150pcs/minute |

| Thickness of Film | 0.03-0.06mm |

| Power | 220v 4.5KW-7.5KW |

| Weight | 1800-2200kgs |

| Overall Dimension | 8300x1700x1700mm |

1). Full Servo Motor control, flexible bag length cutting. Save time and film.

2). 7 inch touch screen, easy operation and multiple language for choice.

3). Smart PLC system, machine performance is stable, convenient for change parameter

4). Self diagnosis failure function, machine error can be clearly displayed in the touch screen.

5). Separate PID temperature controller, suitable for various packing materials

6). High sensitivity optical photocell for eye mark tracking, digital input for cutting position.

7). Position stop function, no adhesive and no waste of membrane and protect cutter.

8). Simple driving system, stable performance and convenient maintenance.

9). According to different products, the input conveyor can use pusher or belt for transportation.

10). High sensitive sensor to track the color mark, so the position of sealing and cutting will be more accuracy.