Have you ever dropped a small “tablet” into water and watched it unfold into a full-sized towel? 😲 That’s the magic of disposable compressed towels — compact, hygienic, and super convenient for modern life on the go!

🌿 What Is a Disposable Compressed Towel?

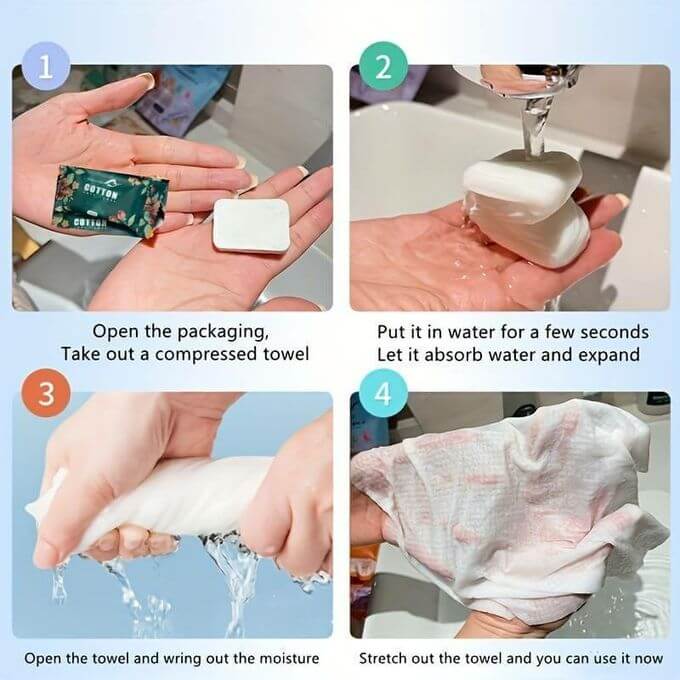

A disposable compressed towel is a small, coin-sized or rectangular piece of nonwoven fabric that expands into a full towel once it comes in contact with water. 💧 It’s individually packed, lightweight, and designed for single use — perfect for keeping things clean and fresh anytime, anywhere.

🧳 Application Scenarios

Compressed towels are a traveler’s best friend! ✈️ Whether you’re on a business trip, camping, hiking, or visiting the gym, they save space while providing hygiene on demand. Common uses include:

- 🏕️ Travel & Outdoor Activities – Easy to carry and dispose of.

- 💼 Business Trips – Compact for luggage, ensures cleanliness.

- 🏖️ Hotel & Spa Use – Hygienic single-use option for guests.

- 🚗 Emergency or Car Use – Perfect for quick cleaning or refreshment.

- 🧒 Baby Care & Personal Hygiene – Gentle and safe for all skin types.

🧵 What Materials Are Used?

Most compressed towels are made from 100% natural cotton or viscose nonwoven fabric.

Some premium ones also mix bamboo fiber for better softness and eco-friendliness. 🌱

✅ Cotton – Soft, absorbent, natural

✅ Viscose – Smooth texture, quick-drying

✅ Bamboo Fiber – Antibacterial, sustainable

🔵 Common Shapes & Standard Sizes

Compressed towels usually come in round and rectangular shapes.

Here are the most common unfolded sizes:

| Shape | Compressed Size | Unfolded Size |

|---|---|---|

| Round | 2–3 cm diameter | 20×20 cm / 25×25 cm |

| Rectangle | 3×6 cm | 30×60 cm / 40×80 cm / 70×140 cm |

💡 Tip: The larger bath towel type (70×140 cm) is great for travel or hotel use, while smaller ones (20×20 cm) are ideal for facial or hand cleaning.

🏭 How Are Compressed Towels Made?

Disposable compressed towels are typically produced using an Automatic Disposable Compressed Towel Folding Compressed & Packing Machine.

The production process involves several automated steps using a Compressed Towel Making & Packing Machine 🤖:

- Nonwoven Fabric Feeding – Raw material is automatically fed.

- Cutting & Folding – Fabric is cut into specific sizes and folded.

- Compressing – High-pressure molds press the towel into compact shapes.

- Film Wrapping – Each piece is wrapped in film or blister packaging.

- Coding – Printing batch number info for traceability.

- Final Packaging – Ready for retail or hotel use.

Modern Automatic Compressed Towel Packaging Machines can handle hundreds of pieces per minute, ensuring hygiene and efficiency. ⚙️