In the wet wipes industry, packaging is not just about aesthetics — it directly impacts product safety, shelf life, transportability, and brand perception. For manufacturers and distributors, understanding the different packaging film materials and their performance is critical to making cost-effective and market-oriented decisions.

1. Structure of Wet Wipes Packaging Films

Wet wipes packaging films are typically laminated structures, combining multiple materials to achieve the required properties:

- Two-layer laminates: PET/PE or OPP/PE

- PET/PE: High clarity, good tensile strength, and excellent sealing.

- OPP/PE: Lightweight, cost-efficient, and offers good printability.

- Three-layer laminates: OPP/VMPET/PE or PET/AL/PE

- VMPET (Vacuum Metallized PET) or Aluminum foil layer provides strong barrier against light, oxygen, and moisture.

- Ideal for wipes with volatile ingredients like alcohol or essential oils.

- High-barrier specialty films: EVOH-based laminates or PVDC coatings are sometimes used for premium products requiring extended shelf life.

👉 The choice of laminate depends on end use (baby wipes, household, medical, or cosmetic wipes) and regional market requirements.

2. Material Properties in Detail

PE (Polyethylene)

- Role: Sealant layer (inner layer)

- Benefits: Flexibility, excellent heat sealability, cost-effective

- Limitations: Low stiffness and printability (usually paired with PET or OPP)

PET (Polyester)

- Role: Outer protective & printable layer

- Benefits: High strength, dimensional stability, good transparency, chemical resistance

- Applications: High-quality printing, premium-looking packaging

OPP (Oriented Polypropylene)

- Role: Outer layer for economy packs

- Benefits: Lightweight, high clarity, cost-saving alternative to PET

- Limitations: Lower heat resistance compared to PET

Aluminum foil or VMPET

- Role: Barrier layer

- Benefits: Blocks UV light, oxygen, and aroma loss; protects active ingredients

- Limitations: Higher cost, reduced flexibility compared to clear films

EVOH (Ethylene Vinyl Alcohol)

- Role: Gas barrier layer

- Benefits: Excellent oxygen barrier while maintaining transparency

- Applications: Medical wipes or products with oxygen-sensitive formulas

3. Packaging Film Performance Criteria

When selecting packaging films, buyers should evaluate the following:

- Barrier Properties

- Moisture vapor transmission rate (MVTR)

- Oxygen transmission rate (OTR)

- UV protection

- Mechanical Strength

- Tensile strength for transport and stacking

- Puncture resistance (important during filling and sealing)

- Sealability & Machinability

- Heat seal strength and sealing temperature window

- Compatibility with high-speed packaging machines

- Printability & Branding

- Surface tension (dyne level) for ink adhesion

- Support for flexographic or gravure printing

- User Convenience

- Easy tear feature for single-use packs

- Resealable adhesive labels or zip-locks for multi-wipe packs

4. Market Trends in Wet Wipes Packaging

Sustainability

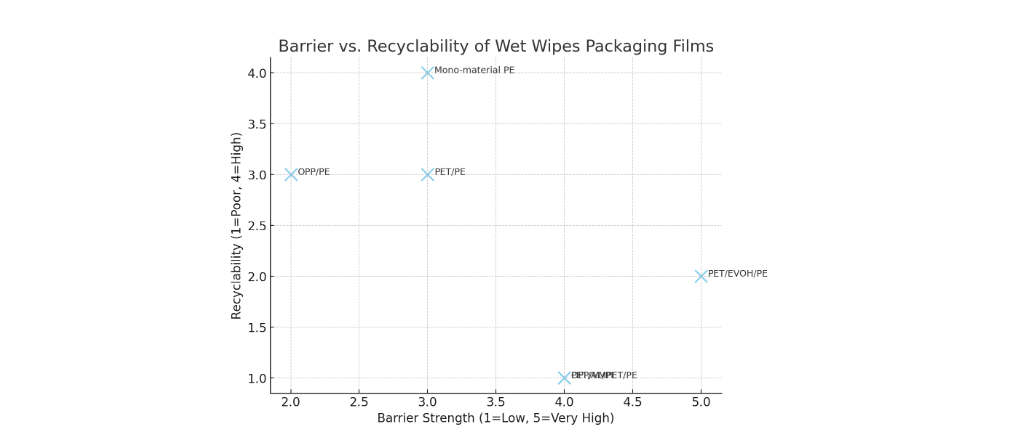

- Growing demand for recyclable mono-material films (e.g., BOPE/PE or MDO-PE laminates).

- Use of bio-based and compostable films (PLA, starch-based) is rising, especially in Europe.

Premiumization

- Brands are investing in matte finishes, metallic effects, and tactile varnishes to differentiate on shelves.

- Smart packaging with QR codes, NFC, or AR features adds marketing value.

Functionality

- Advanced resealable labels with improved adhesives for repeated opening/closing.

- Antibacterial coatings on film surfaces for healthcare wipes.

5. Cost vs. Performance Considerations

Packaging selection often comes down to balancing:

- Cost efficiency (OPP/PE laminates for household wipes)

- Product protection (PET/AL/PE for alcohol-based wipes)

- Market positioning (bio-based or premium packaging for eco-conscious and cosmetic brands)

Example: A baby wipes manufacturer may prioritize softness, resealability, and eco-friendliness, while a medical wipes producer will focus on barrier strength and sterilization compatibility.

6. Summary & Buyer Recommendations

| Application Type | Recommended Film Structure | Key Advantages |

|---|---|---|

| Baby wipes | PET/PE or BOPE/PE | Safe, durable, printable, recyclable options |

| Household cleaning | OPP/PE | Cost-effective, good clarity, fast sealing |

| Alcohol-based wipes | PET/AL/PE or OPP/VMPET/PE | Excellent barrier, prevents evaporation |

| Medical/disinfectant | PET/EVOH/PE | High oxygen barrier, chemical resistance |

| Cosmetic wipes | PET/PE with matte finish | Premium look, brand differentiation |

| Eco-friendly products | Mono-material PE laminates | Fully recyclable, meets sustainability goals |

Final Thoughts

For wet wipes manufacturers and importers, choosing the right packaging film is a strategic decision. It affects not only the product quality and shelf life, but also the brand image and compliance with environmental regulations.

As global demand for wet wipes grows, investing in advanced and sustainable packaging films will give your business a competitive advantage in both traditional and eco-conscious markets. 🌍